ZEN

Using 3D printing, create a wireless charger that allows me to utilise the standby function of my iPhone 11. The design must match the current aesthetics of its intended environment, my bedroom, and incorporate at least one alternative material and manufacturing process.

2024

Product Design

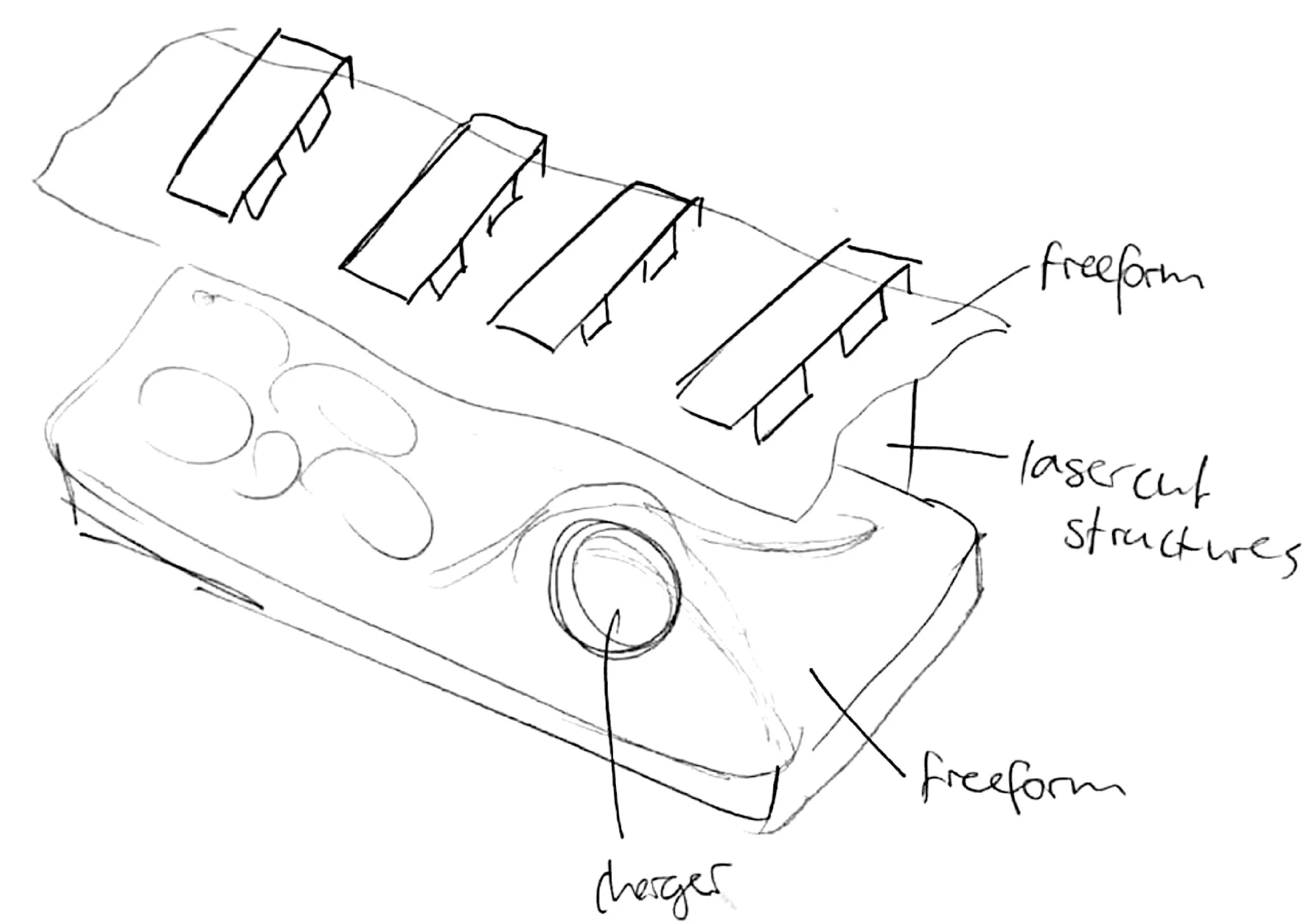

Ideation

I find a lot of comfort in introducing memories of my travels into my surroundings

I drew inspiration for this project from my two visits to Japan in 2024.

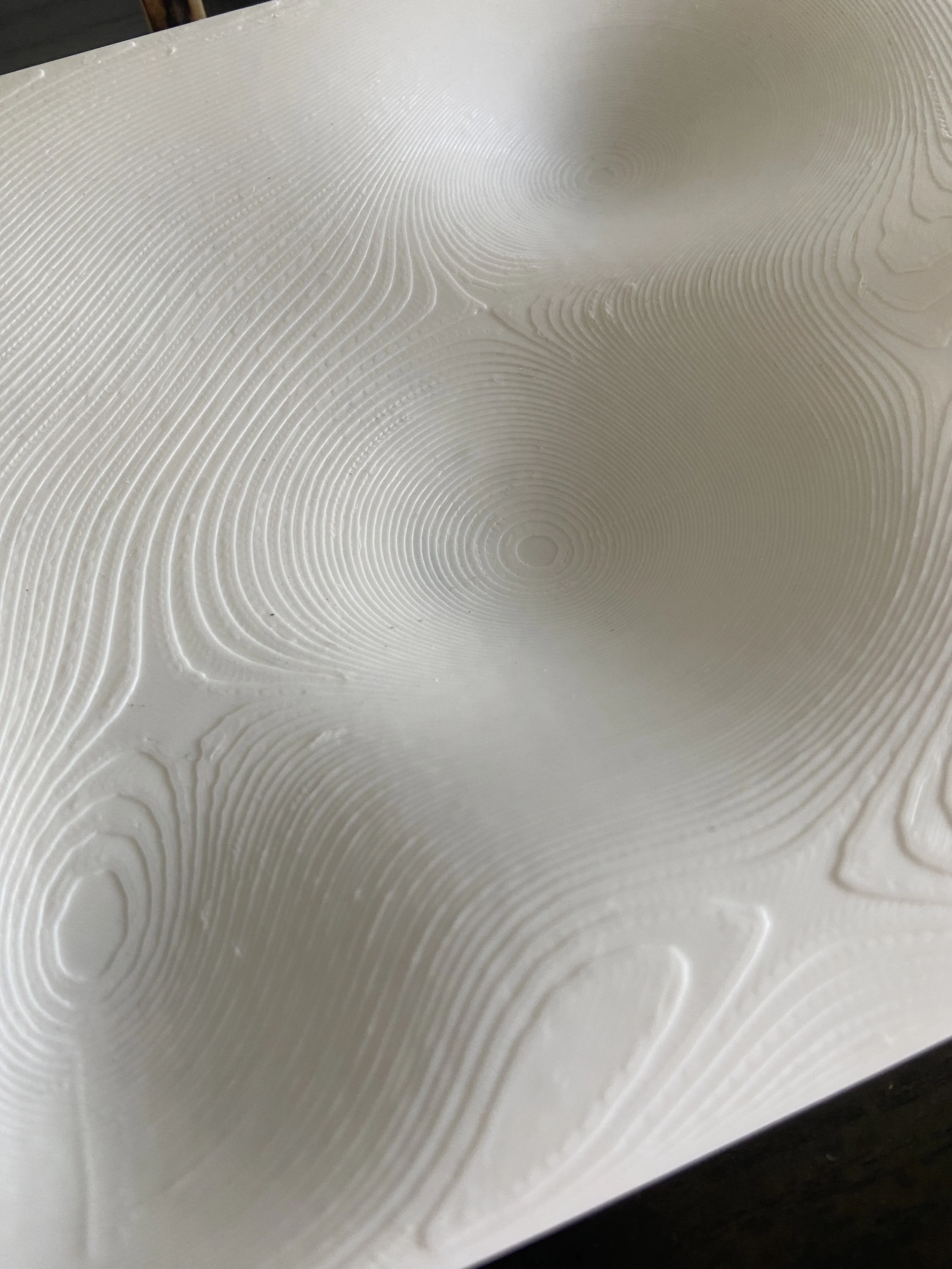

I drew particularly from the gardens of Nijo Castle in Kyoto, with the hope to incorporate elements of the sand and water of these gardens which I found so peaceful.

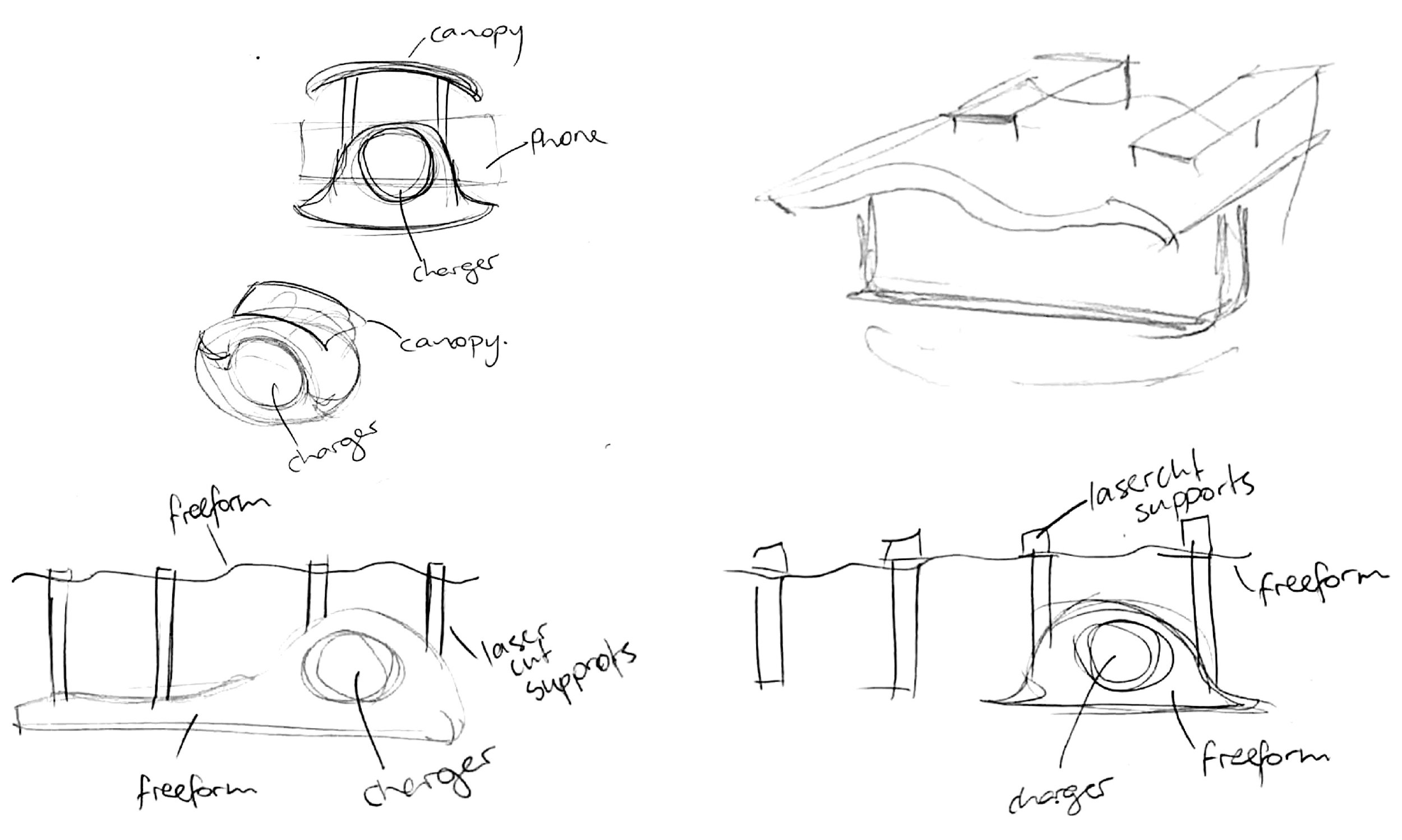

As seen in my sketches, I incorporated this peaceful motion with the minimalistic parallel lines seen throughout Japanese design.

Modelling & Production

3D Printer limitations presented the greatest challenges throughout the production process.

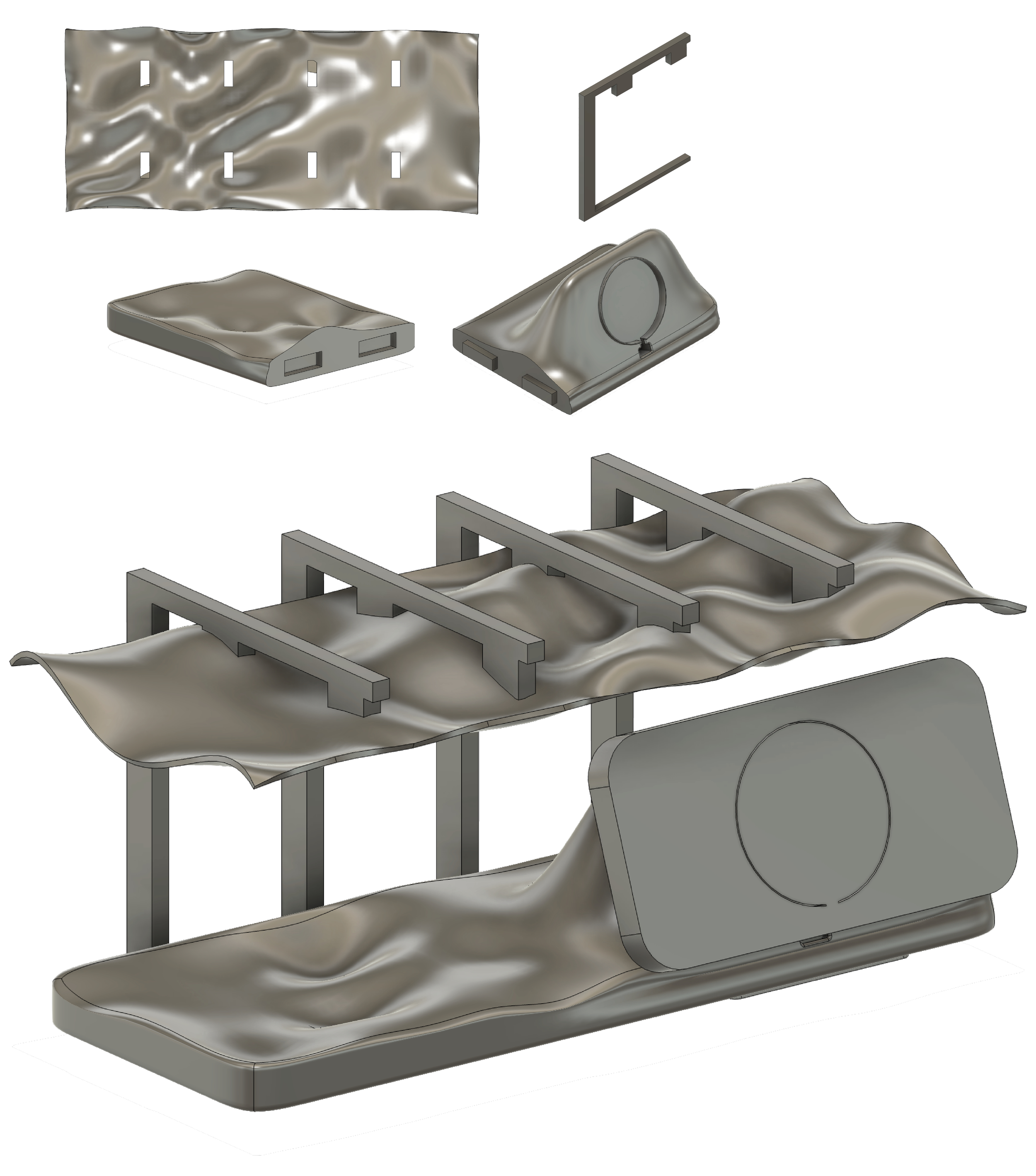

The final model was created in Fusion360.

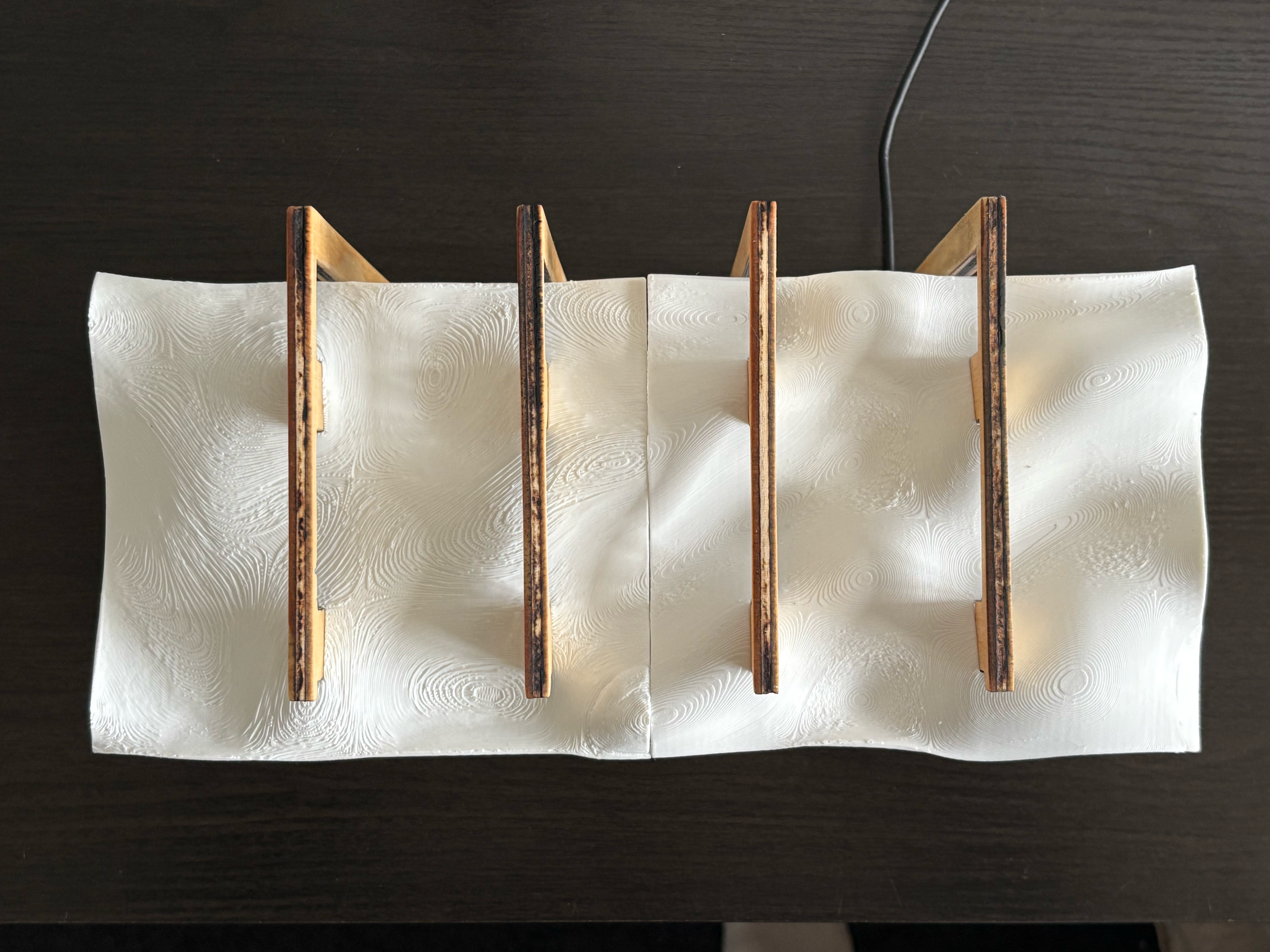

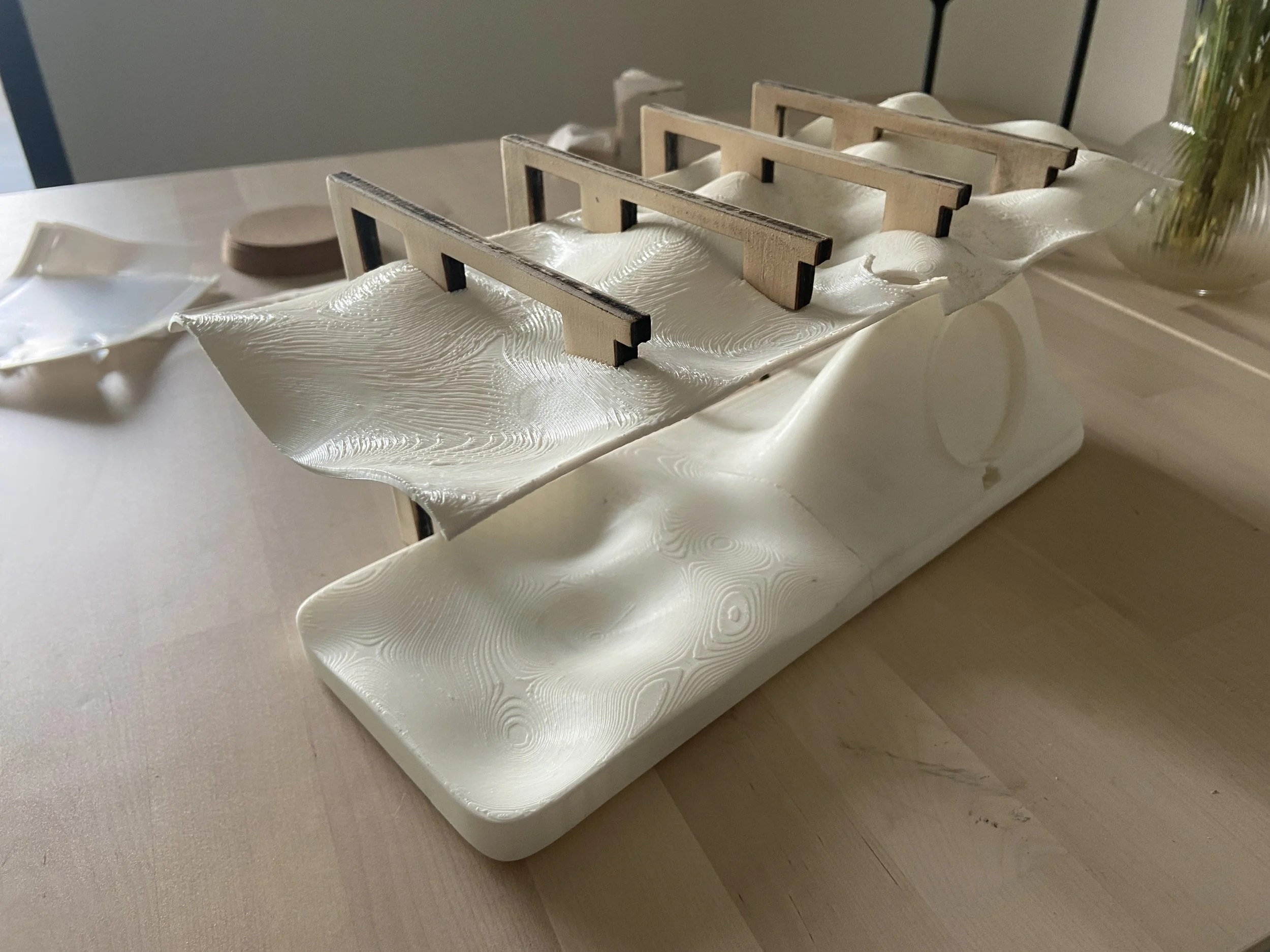

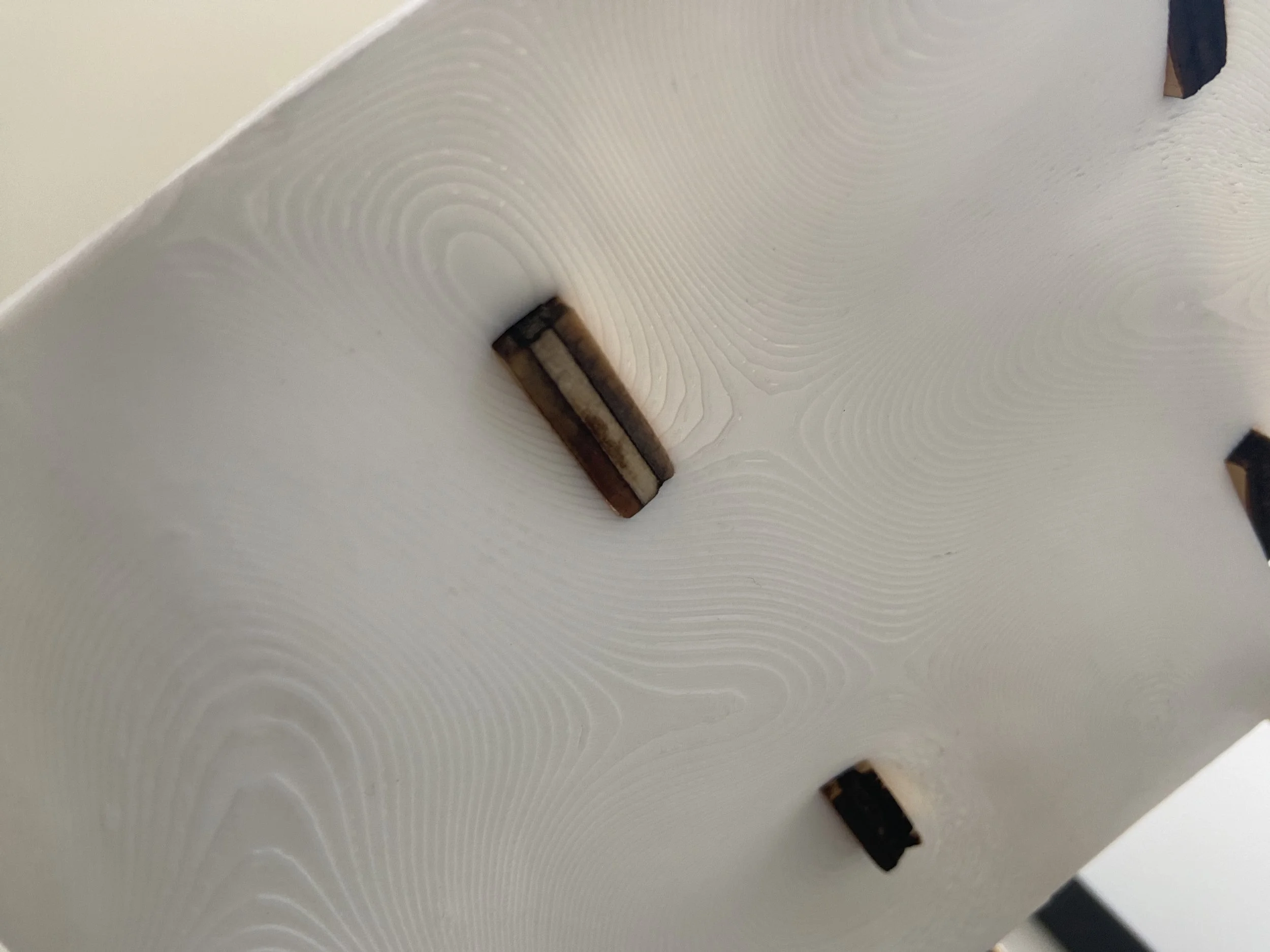

Due to the size limitations of the 3D printer, the model’s base and overhang components were divided in half for printing and are connected via two push fit tabs.

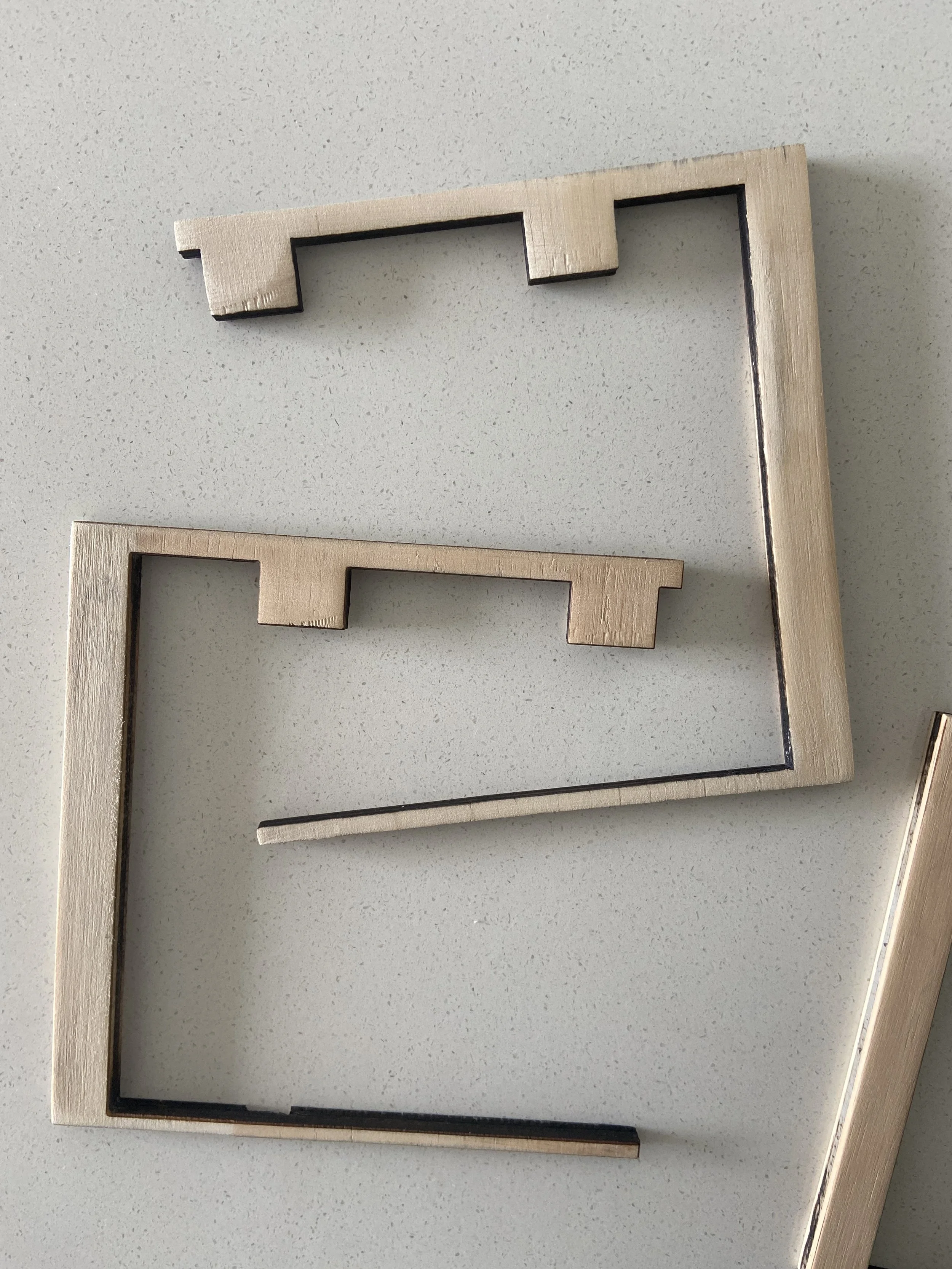

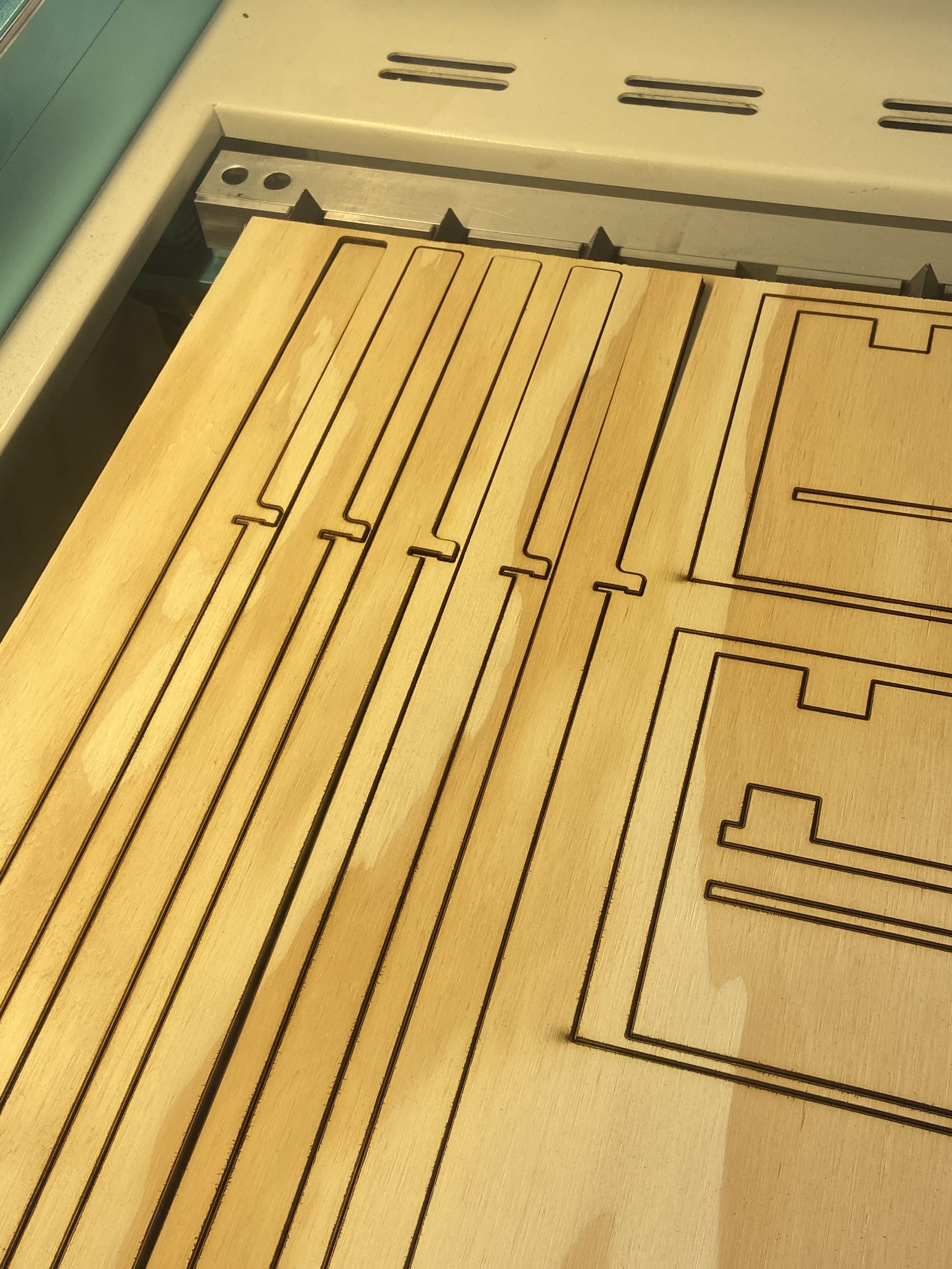

A template for the four identical support pieces was also modelled in Fusion360 and exported to Lightburn for laser cutting from 7mm plywood.

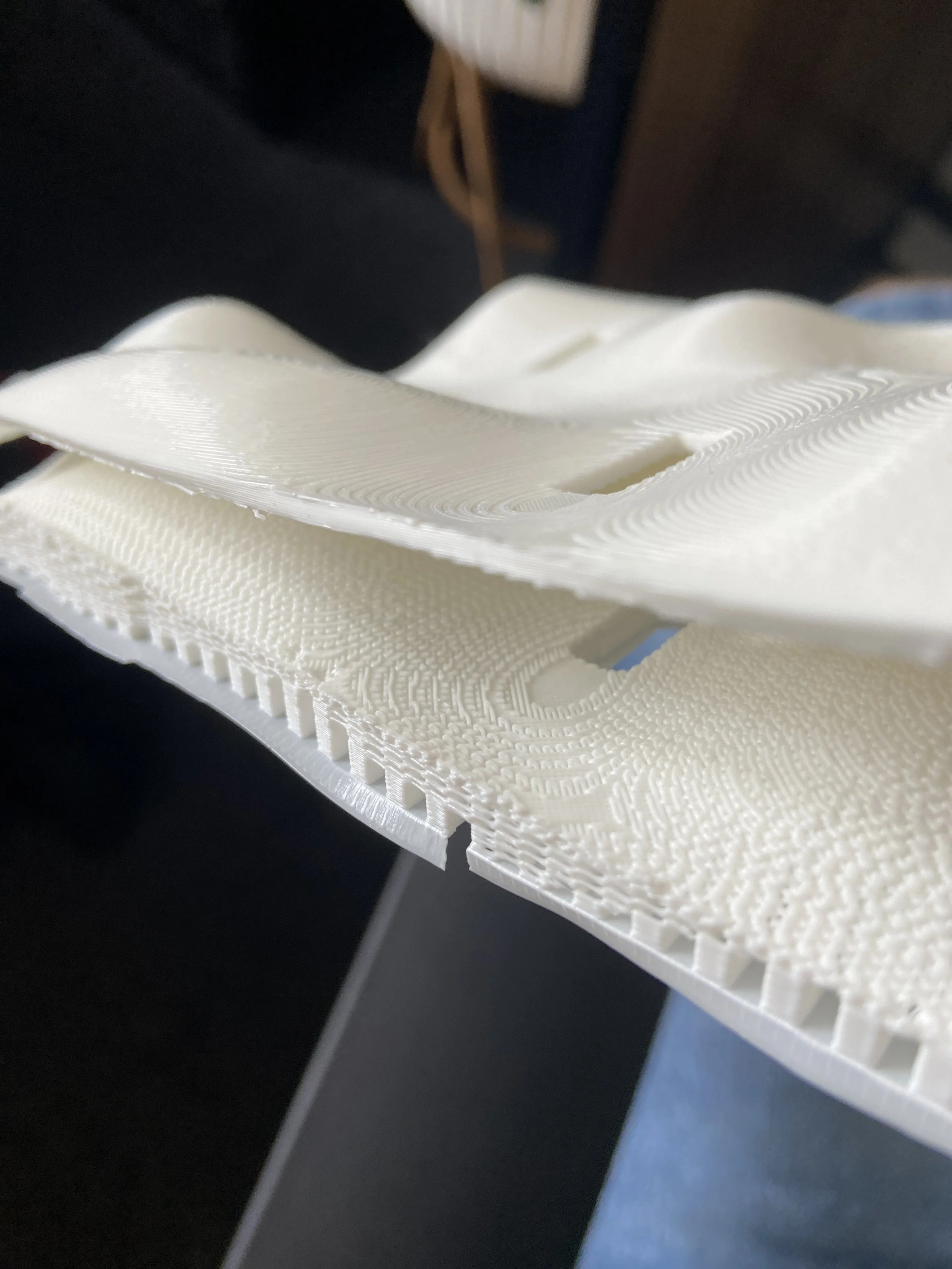

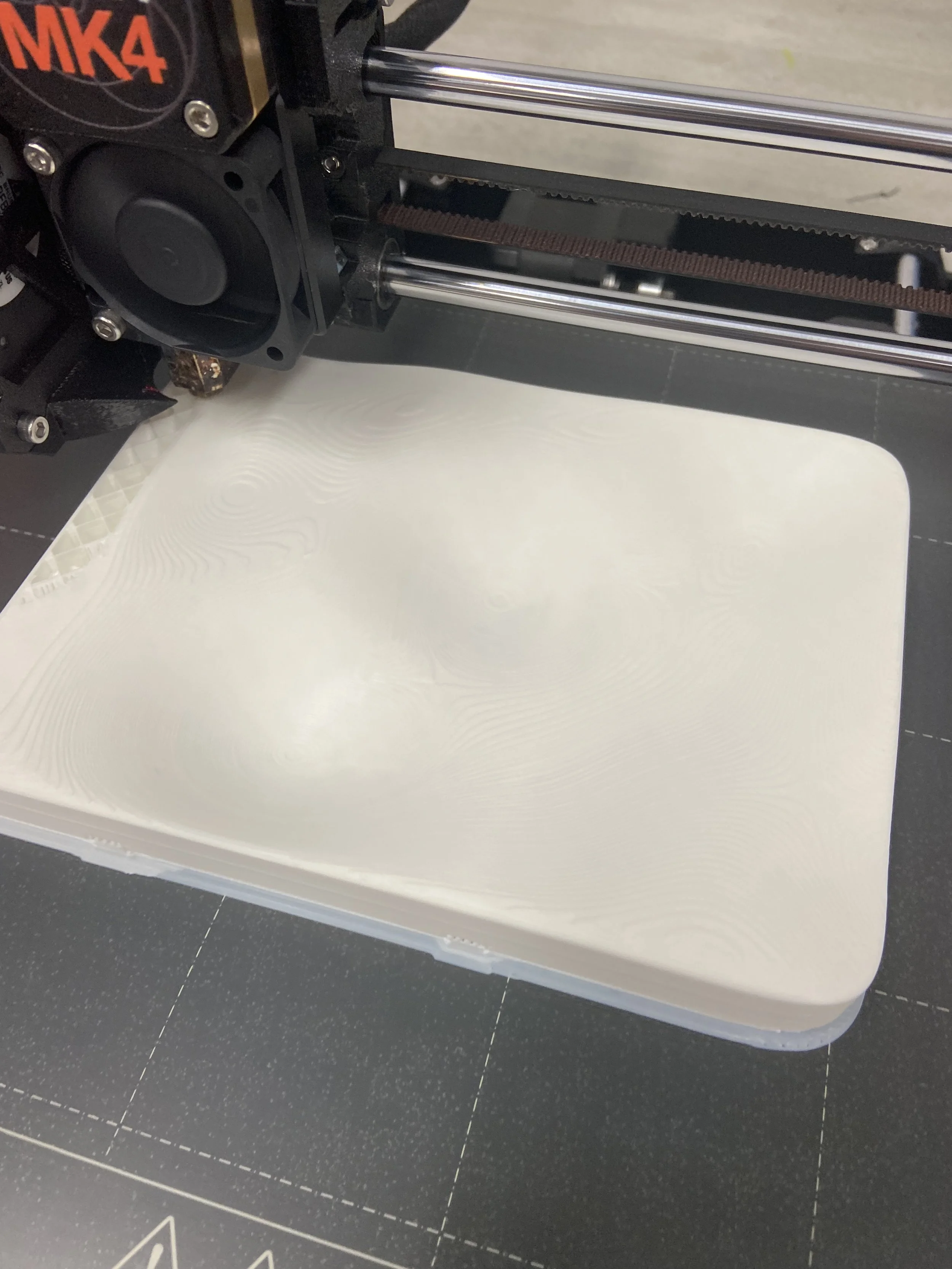

The 3D printing process presented numerous bed adhesion issues which were eventually subsided by adding a raft to the print. The total print time totalled to approximately 80 hours.

Due to the organic nature of the pieces, particularly the overhang pieces, a great number of supports were required for each print. In the future I would love to further this design by using 3D printing as a means to cast a mould for the final material instead such as plaster, epoxy or concrete.

Final Product