VESSEL

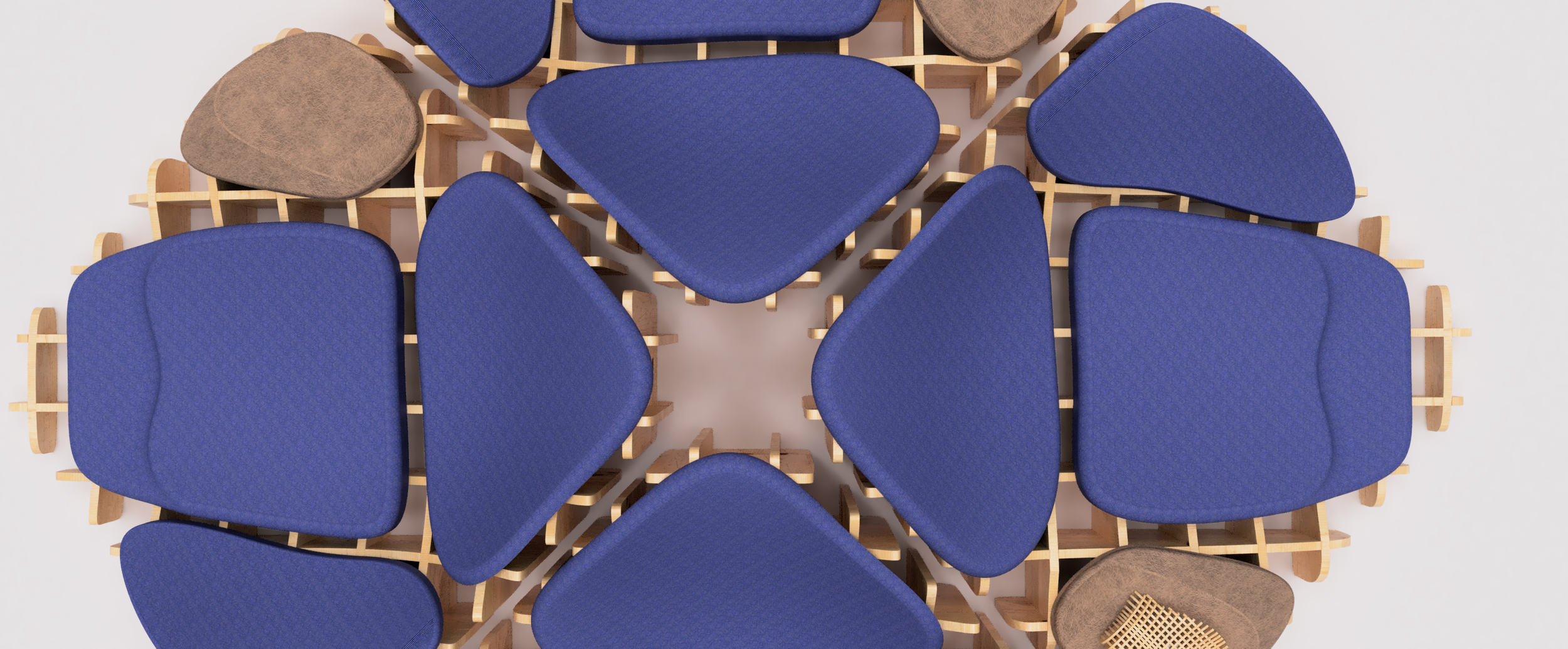

Design and build a statement furniture piece to be made in a commercial workshop with sustainable materials.

2025

Product Design

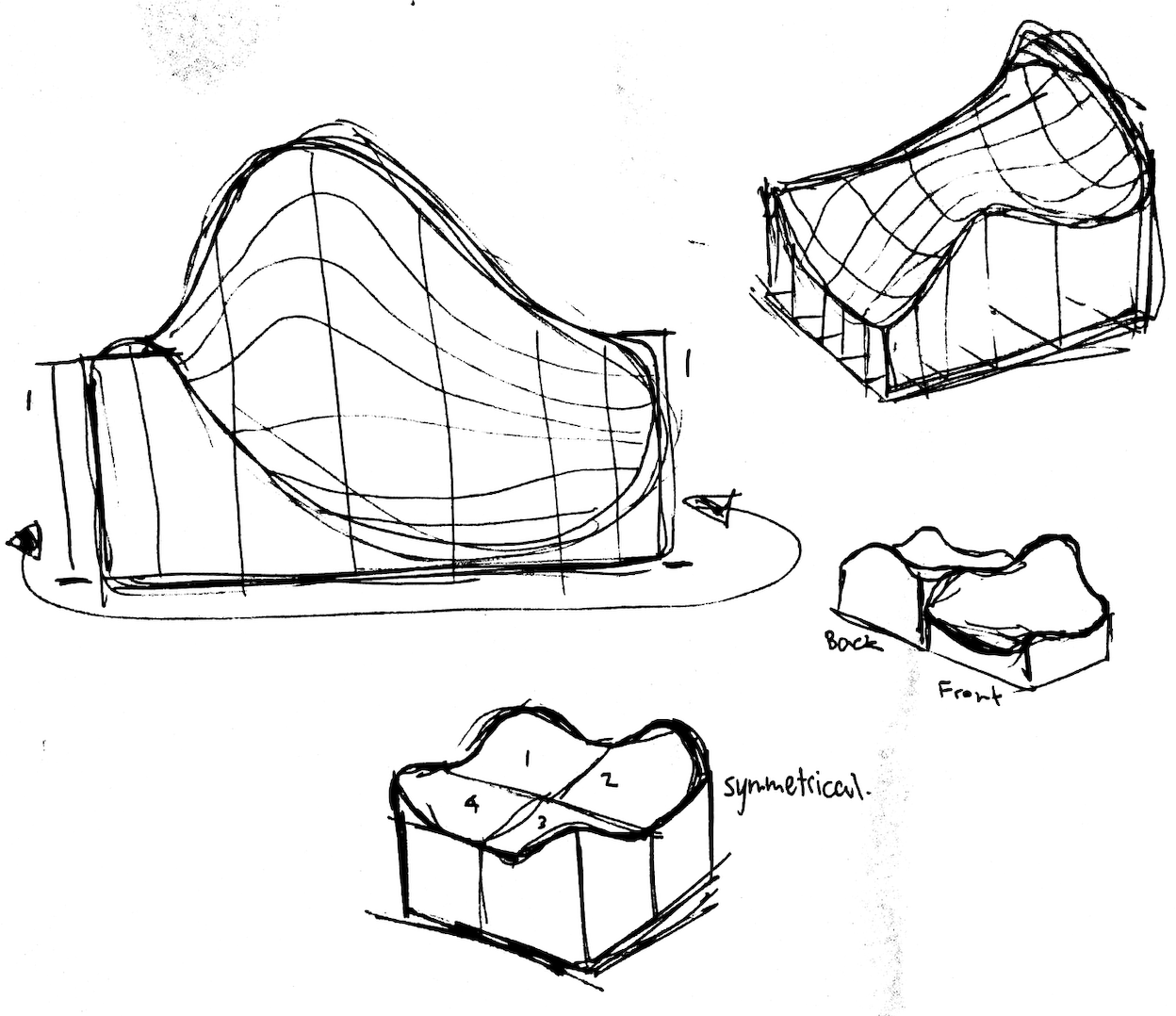

Ideation

The chair shouldn’t be something that impedes or competes with the user’s experience, instead, compliment and enable it.

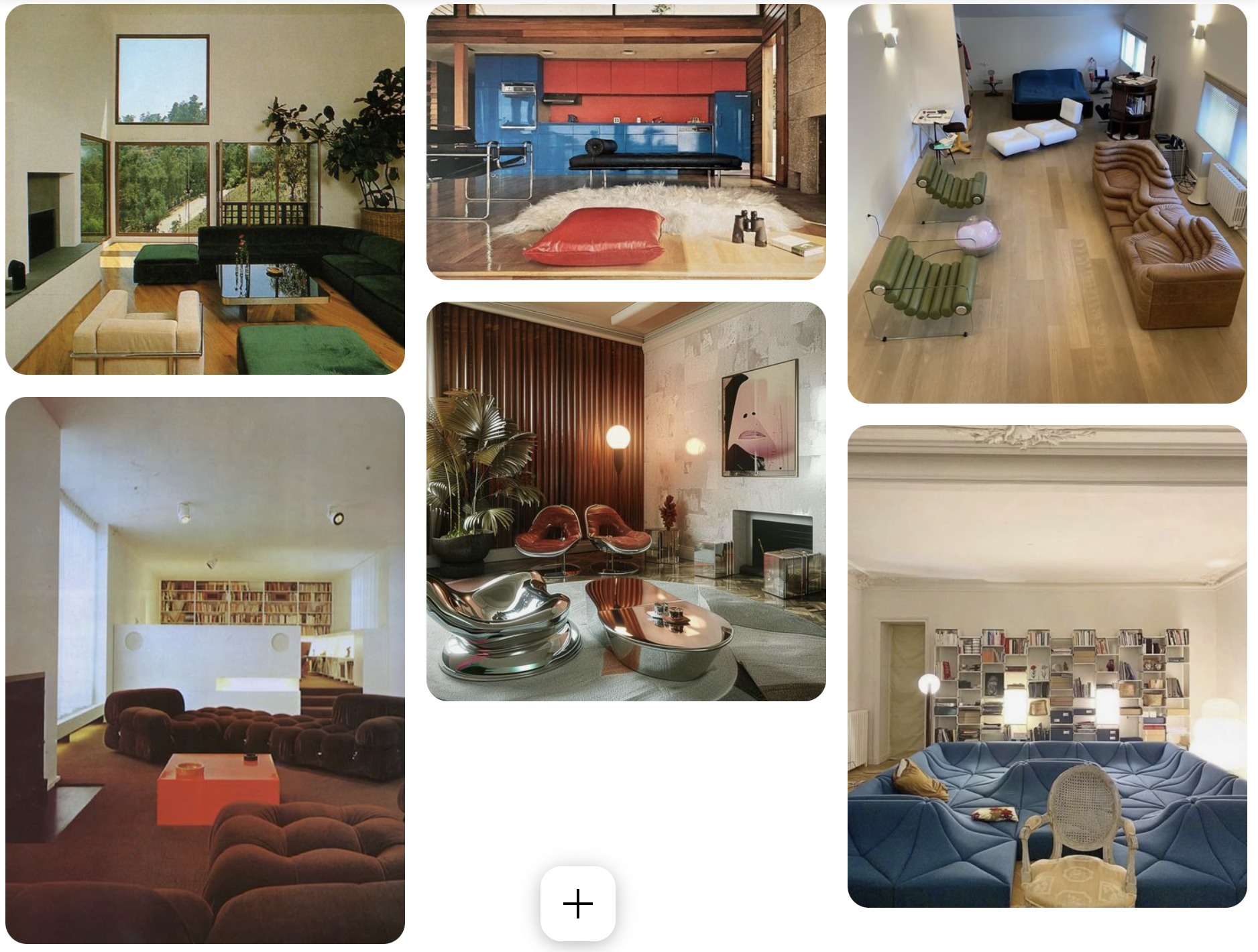

My contextual moodboard

The ‘Dune Ensemble’ by Pierre Paulin

My inspiration for the project came from Pierre Paulin’s ‘Dune Ensemble’. A sofa from 1970. The modular couch is comprised of typically four pieces repeated in a 12–20-piece configuration, where each piece is made to seamlessly fit with one another. The sculptural form and modular configuration of the sofa give it an infinite number of uses, and no one sofa must be the same, nor the users experience with it.

What I love about this sofa is its experience. It gives the user the freedom to create their own experience and adapt to their life. The sofa is a lounging experience that doesn’t define how it must be sat or laid upon.

Modelling & Production

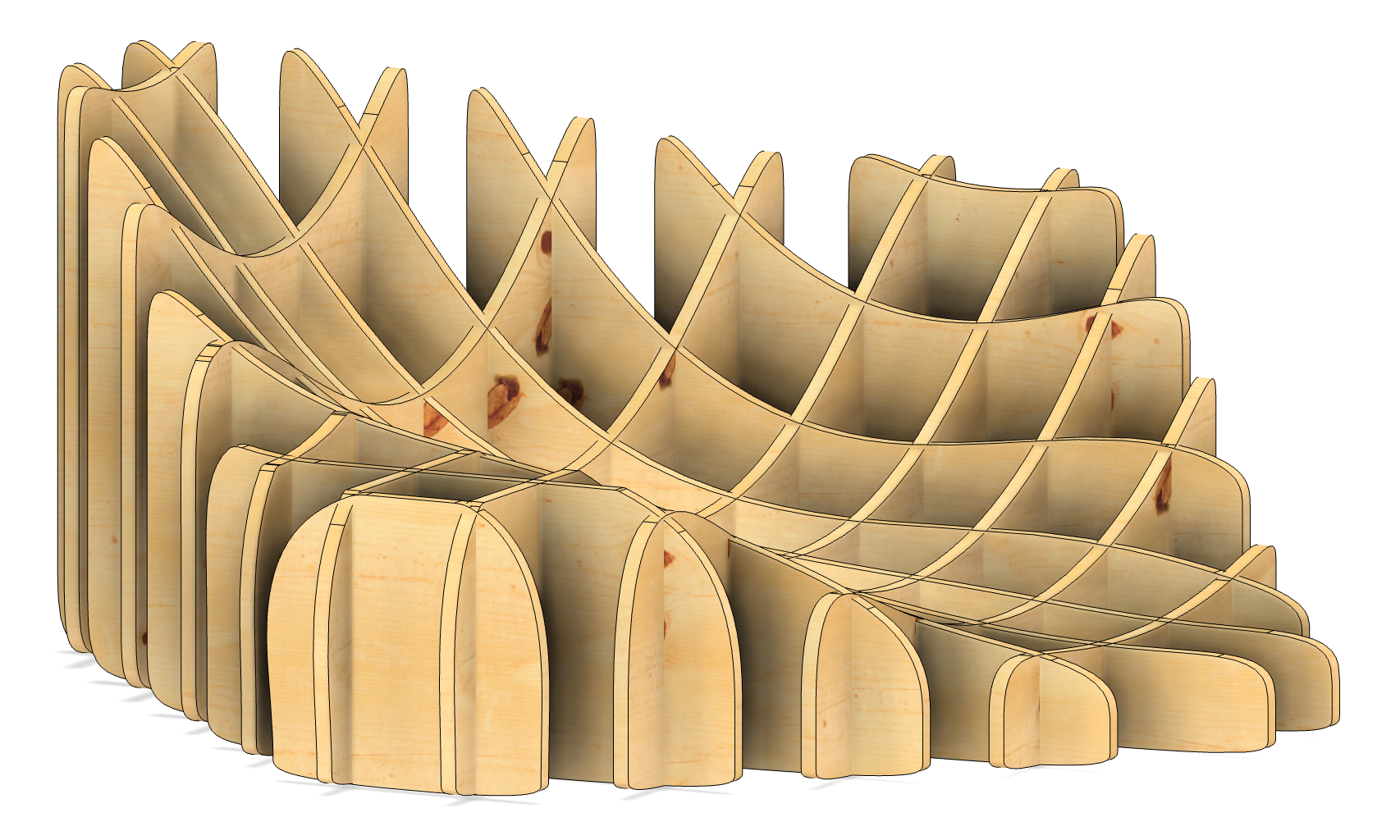

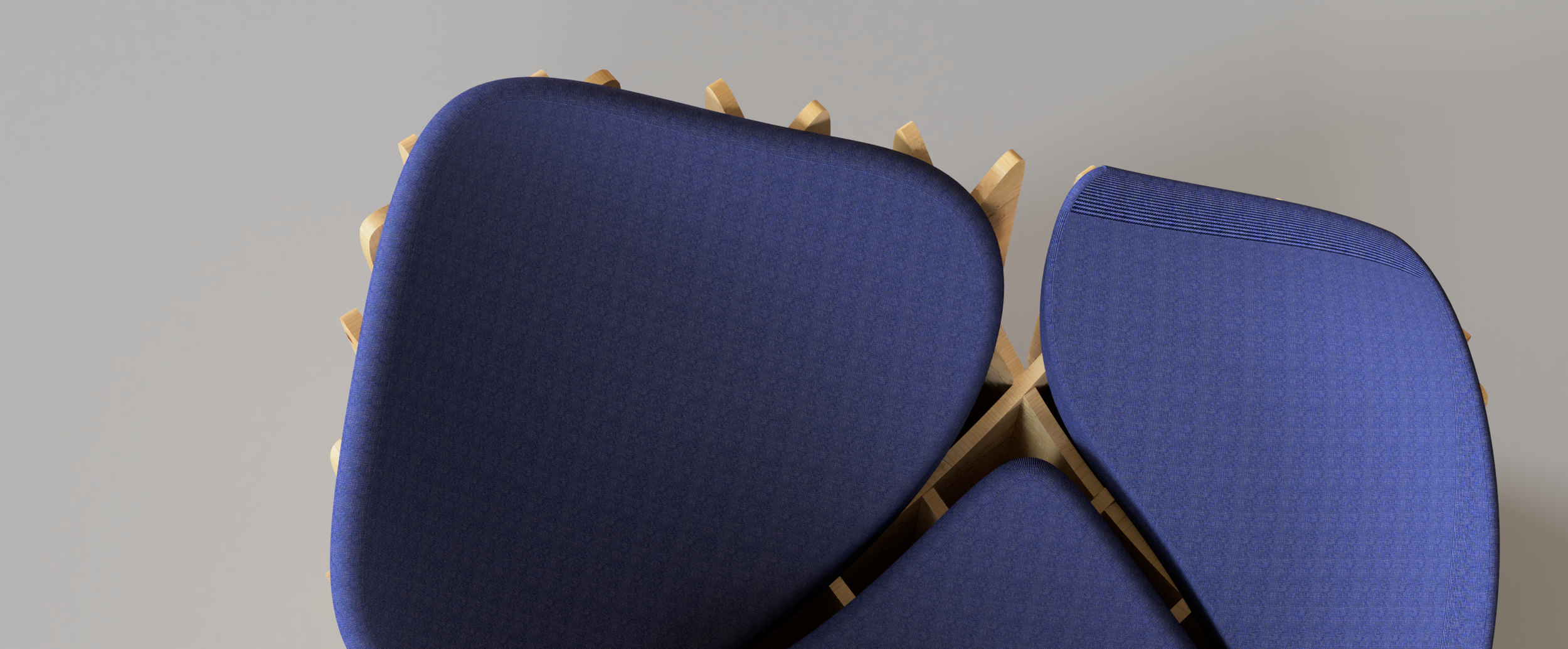

Form and tolerances dictated the greatest changes throughout the process.

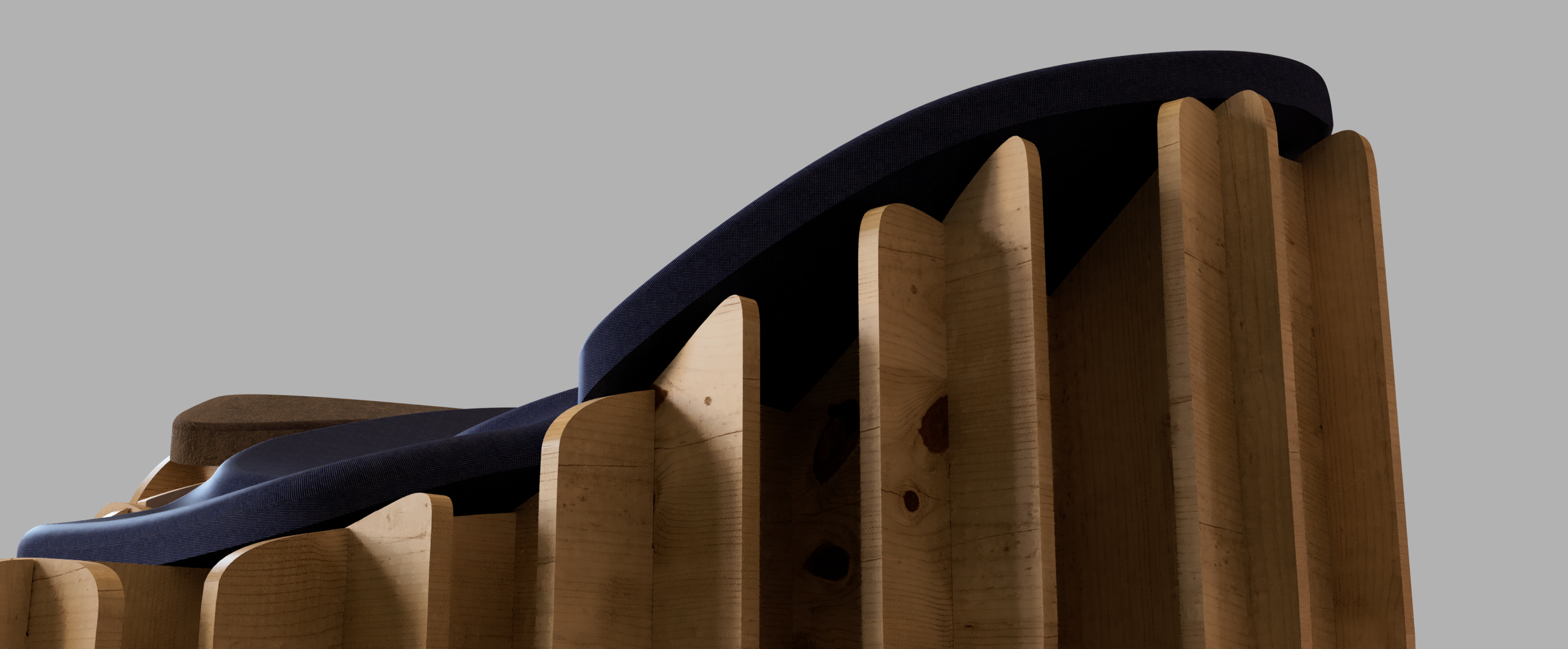

I made a 1:10 scale model out of air-dry clay. The process was brilliant in forming my understanding of the balance of the dimensions of the chair. I enjoyed being able to so easily manipulate the form, it made iterating very quick because changes could be made in seconds.

Continuing the prototyping process, I turned to a 1:1 scale model. Due to the organic form of the concept, creating a quick, adaptable prototype was challenging to create out of traditional materials like cardboard.

Therefore, I repurposed my bed’s duvet cover and added support under the required spots to determine the most comfortable dimensions of the form.

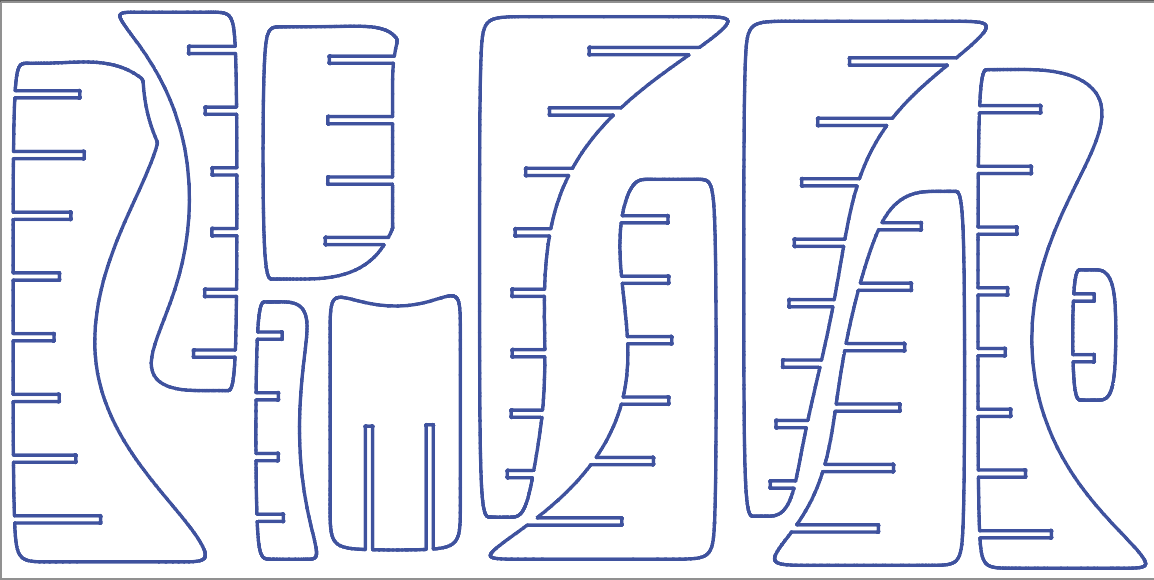

I was informed of a discontinued fusion software called Slicer. Because the software is discontinued, the nesting feature is ineffective, however, I was able to edit this from 4 sheets to 2 sheets in Adobe Illustrator, bringing the cost down to $300 in plywood.

Construction

Final Product

Branding Application